Industry 4.0, often referred to as the Fourth Industrial Revolution, represents the next stage in manufacturing and industrial evolution, characterised by the fusion of physical production with digital technologies. It integrates cyber-physical systems, the Internet of Things (IoT), cloud computing, big data analytics, and artificial intelligence (AI) to create smart factories and interconnected ecosystems that enable greater automation, real-time data exchange, and flexible manufacturing.

What Are Cyber-Physical Systems and the Role of IoT?

Cyber-Physical Systems (CPS) represent a convergence of computational elements and physical processes. Unlike traditional automation, CPS tightly couple software and hardware through embedded sensors, actuators, and communication networks. This integration allows real-time monitoring, control, and feedback, creating adaptive systems capable of autonomously responding to complex environments.

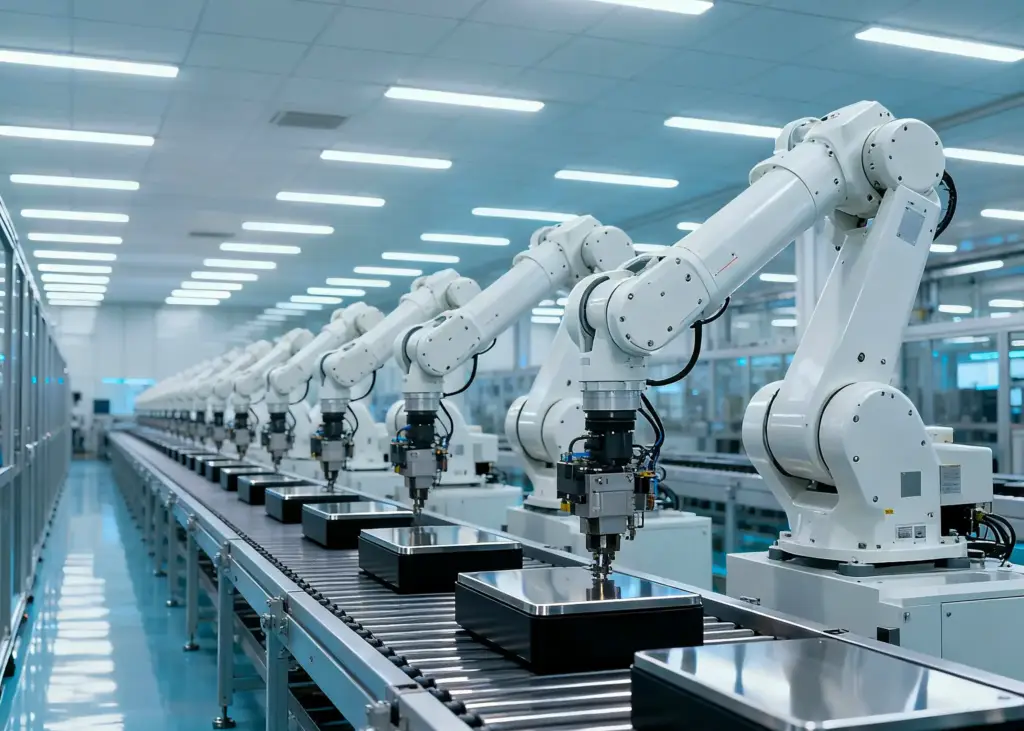

IoT devices — sensors, smart meters, connected machinery—are the vital elements that collect vast amounts of real-time data, providing the “nervous system” for CPS. IoT acts as the connective tissue, enabling physical objects such as robotic arms, vehicles, or energy grids to send data on temperature, movement, wear, and environmental conditions. This data empowers CPS to respond dynamically, facilitating smarter decision-making, predictive maintenance, and autonomous operation.

IoT’s Central Role in Industry 4.0

The transformation brought by IoT-enabled CPS makes possible:

- Real-Time Monitoring and Control: Sensors embedded in assets provide live data streams for instant analysis, allowing immediate responses to operational anomalies or opportunities.

- Predictive and Prescriptive Maintenance: IoT sensors continuously monitor equipment health, enabling CPS to predict failures before they happen and prescribe corrective actions without human intervention.

- Mass Customization and Flexibility: IoT facilitates rapid reconfiguration of manufacturing lines based on real-time demand signals, reducing waste and lead times.

- Supply Chain Visibility: IoT tracking devices offer end-to-end transparency across transportation, warehousing, and inventory management, optimizing logistics workflows.

- Enhanced Safety and Efficiency: IoT sensors detect hazardous conditions and automatically adjust operations or alert personnel, reducing risk and downtime.

Challenges and Opportunities in IoT-Driven CPS

While IoT enriches CPS capabilities, deploying large-scale IoT networks involves challenges such as cybersecurity, data privacy, interoperability, and scalability. Overcoming these hurdles is critical to unlocking the full potential of Industry 4.0.

Future Prospects

Advances in 5G connectivity and edge computing will further empower IoT within CPS, enabling higher-density sensor networks, faster data processing, and more autonomous systems. The nexus of IoT and CPS will continue to enable intelligent, resilient industrial ecosystems capable of adapting to changing demands and environmental conditions.

Conclusion

IoT is the backbone that enables CPS to deliver on the promises of Industry 4.0 — smart manufacturing, autonomous operations, and predictive insights. Embracing IoT-enabled CPS is vital for companies aiming to stay competitive in an increasingly digital and interconnected world. At the forefront of this shift, Global Research emphasizes the importance of IoT as a transformative driver for industrial innovation and economic growth.